Impact of the Global Semiconductor Shortage

Introduction: Understanding the Semiconductor Shortage

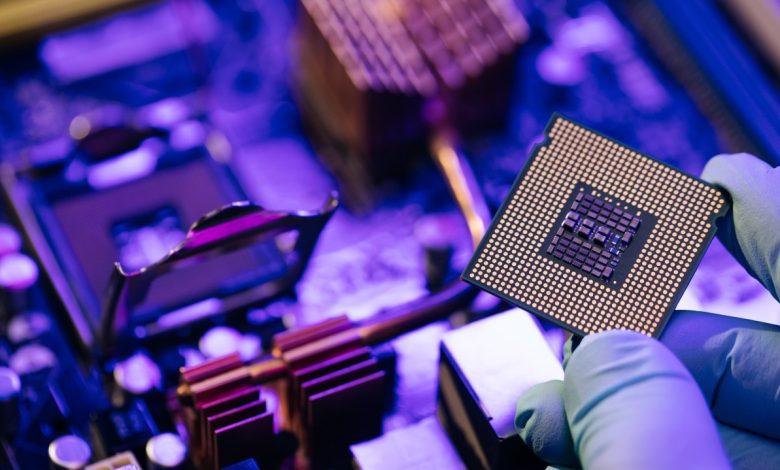

Semiconductors power the modern world. These tiny chips drive everything from smartphones and computers to cars and household appliances. In recent years, however, a global shortage of semiconductors has caused significant disruptions across multiple industries. This shortage, fueled by pandemic-related supply chain issues, rising demand, and complex manufacturing requirements, has impacted production and the economy on a global scale. The shortage’s effects are widespread, and resolving it is proving challenging.

The Causes of the Semiconductor Shortage

The semiconductor shortage did not happen overnight. Multiple factors converged to create this crisis.

1. Pandemic Disruptions

The COVID-19 pandemic caused an unprecedented disruption to global supply chains. Factory shutdowns, labor shortages, and strict lockdowns halted production lines around the world. At the same time, the demand for electronics surged as people transitioned to remote work and online learning, putting further pressure on chip manufacturers.

2. Increased Demand for Electronics

As digital transformation accelerated, demand for electronic devices skyrocketed. Laptops, gaming consoles, and smartphones saw record sales during the pandemic. This surge in demand led to chip supply constraints, as manufacturers could not keep up with orders. Additionally, the rise of the Internet of Things (IoT) has increased the need for semiconductors, as everyday items become more connected.

3. Complex Production Process

Manufacturing semiconductors is complex and resource-intensive. Each chip requires specialized facilities, often costing billions to build. Additionally, the production process involves multiple steps, including design, testing, and fabrication. As a result, it takes months to produce a single semiconductor, making it difficult to quickly scale production in response to rising demand.

4. Geopolitical Tensions

Trade tensions between major economies, particularly the U.S. and China, have also played a role. Restrictions on chip exports and imports have complicated global supply chains. Some companies have been forced to shift production to avoid these tariffs, causing further delays and bottlenecks in the supply chain.

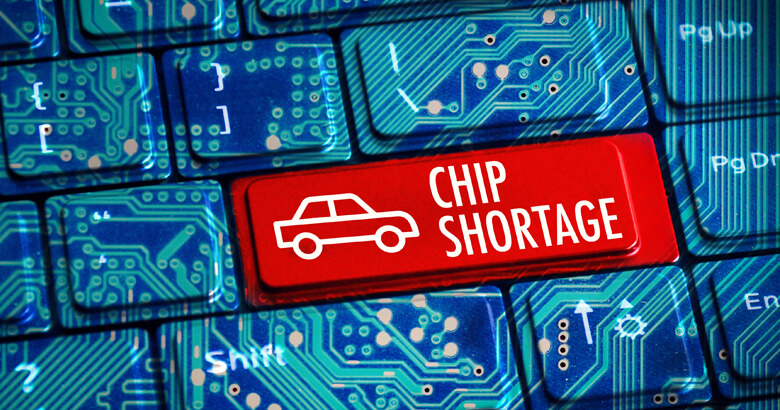

Impact on the Automotive Industry

The semiconductor shortage has hit the automotive industry particularly hard. Modern vehicles rely heavily on chips for a range of functions, including safety features, navigation systems, and entertainment.

1. Production Delays

Due to chip shortages, many car manufacturers have had to delay or scale back production. Automakers around the world have been forced to halt assembly lines, reduce output, and, in some cases, temporarily close factories. Major brands like Ford, Toyota, and General Motors have all reported significant production setbacks due to the shortage.

2. Price Increases

As the supply of new cars has dropped, prices for both new and used vehicles have risen. Consumers are facing higher costs as demand outweighs supply. This situation has created a ripple effect in the market, with car rental companies and auto repair shops also experiencing increased costs and wait times.

3. Shift Toward Simplified Models

Some automakers have adapted by producing simplified versions of vehicles with fewer tech features. For example, models may come without premium features, such as advanced infotainment systems, to conserve available chips. While this helps meet demand, it reduces options for consumers seeking advanced features in their vehicles.

Effects on Consumer Electronics

Consumer electronics are another sector deeply affected by the semiconductor shortage. The high demand for gadgets has collided with limited chip supply, creating shortages and price hikes.

1. Smartphone and Computer Shortages

Smartphones and laptops rely heavily on semiconductors. With the shortage, manufacturers have struggled to keep up with consumer demand. Leading brands like Apple and Samsung have faced production challenges, causing delays and limited availability of new models. Additionally, laptops, which became essential for remote work, have been hard to find, especially models with high-performance specifications.

2. Gaming Console Delays

Gaming consoles, such as the PlayStation 5 and Xbox Series X, have experienced severe shortages since their launch. With limited chips, manufacturers have been unable to produce enough units to satisfy demand. As a result, many gamers face months-long wait times or pay premium prices from resellers.

3. Price Increases in Electronics

Due to scarcity, prices for consumer electronics have risen. Higher component costs are being passed on to consumers. This price increase affects various products, from smartphones and laptops to gaming consoles and household appliances.

Broader Economic Impacts

The semiconductor shortage extends beyond specific industries, impacting the global economy and inflation rates.

1. Slowed Economic Recovery

As economies recover from the pandemic, the semiconductor shortage is slowing growth. Industries reliant on chips are struggling to regain pre-pandemic production levels. This slowdown in production delays the broader economic recovery, particularly in countries with large automotive and electronics manufacturing sectors.

2. Inflation Pressure

Shortages and supply chain bottlenecks are driving up costs for businesses. These increased costs often lead to higher prices for consumers. The rise in prices for products like cars, electronics, and home appliances contributes to inflation, making everyday goods more expensive. This pressure on inflation affects purchasing power, potentially slowing consumer spending.

3. Workforce Impact

The shortage has also affected the workforce. Some factories have reduced hours or laid off workers due to limited production capacity. On the other hand, the shortage has increased demand for skilled labor in semiconductor manufacturing and supply chain management, leading to new job opportunities in these areas.

Solutions and Industry Adaptations

Addressing the semiconductor shortage is challenging. However, several solutions are being explored to prevent future crises.

1. Increased Investment in Chip Manufacturing

Governments and companies are investing heavily in semiconductor manufacturing. The U.S., Europe, and China have announced plans to expand local production to reduce dependence on foreign suppliers. For instance, the U.S. recently passed the CHIPS Act to encourage domestic chip production. While these investments will take time to yield results, they could help stabilize supply in the long run.

2. Diversification of Supply Chains

Companies are diversifying their supply chains to reduce reliance on single suppliers. By sourcing chips from multiple regions, businesses can better manage disruptions. Additionally, establishing regional supply chains reduces transportation delays, ensuring a more resilient network.

3. Development of Alternative Technologies

Some companies are researching alternative technologies to reduce reliance on traditional semiconductors. For example, quantum computing and advanced AI chips may reduce dependence on silicon-based semiconductors in specific applications. While still in early stages, these technologies could help alleviate demand for traditional chips over time.

The Future of the Semiconductor Industry

The global semiconductor shortage has highlighted the importance of chips in modern society. As industries continue to adopt digital technologies, demand for semiconductors will only grow. Future growth in areas like artificial intelligence, 5G, and electric vehicles will further drive demand for chips.

To prevent similar crises, the semiconductor industry must increase capacity and improve resilience. Governments, companies, and technology leaders must collaborate to ensure a stable supply of semiconductors, especially as demand for digital devices continues to expand.

Conclusion: Lessons from the Semiconductor Shortage

The global semiconductor shortage has shown how crucial these tiny chips are for the modern economy. From cars to electronics, semiconductors drive much of today’s technology. This crisis serves as a lesson in the importance of resilient supply chains and increased production capacity. By investing in manufacturing, diversifying supply chains, and exploring new technologies, the industry can better prepare for future challenges. Although solutions will take time, the steps taken today will help build a more stable semiconductor supply chain for tomorrow.